FluoroGrip® Lightning Strike Protective Film Coatings

Current systems utilizing embedded metallic foils require costly maintenance and repair once the object incurs a lightning strike event. Integument’s LS-1000 acts as a sacrificial surface layer that protects underlying composites and can be easily repaired by simply removing from the damaged area and replacing it with a new section.

Advantages

- Protects underlying materials from direct lightning strikes and other electromagnetic environmental effects

- Designed as a sacrificial lighting strike protective layer that can be easily maintained and repaired upon damage from lighting or mechanical damage

- Provides high performance protection against corrosion and weathering

- Peel and stick adhesive backing which allows it to bond to almost any surface

- Mechanical performance, environmental durability and thermodynamic stability over the typical life cycle of the structure or equipment it is bonded to

- Provides outstanding chemical resistance to cleaning solvents, oils, and fuels

- Environmentally friendly corrosion protection of the surface or the structure

Typical Applications and Use

- Windmills

- Composite Aircraft

- Composite based equipment

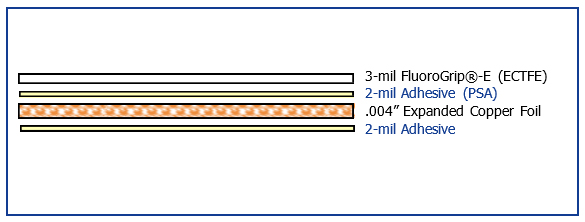

FluoroGrip® Lightning Strike Film Coating Lay-Up

LS-1000® – is available standard with 3 mil FluoroGrip®-E (ECTFE), .004” expanded copper foil, and a new acrylic-based pressure sensitive

adhesive system. LS-1000® can also be customized to have a desired color, different gauge, weight or specific metallic foil, and customized adhesive systems for applications that may require specifications outside the scope of the offered product.

Easy to install for enhanced maintenance procedures

FluoroGrip® lightning strike films offer peel and stick installation and can be easily applied by hand on composite or metallic structures.

- Films are easily cut to match the size and shape of the desired surface area

- Acts as a sacrificial layer that can be removed and replaced once the area has been damaged due to a lightning event

- Does not require primers or hazardous solvents, and the solid sheet design assures consistent coverage, even on edges, angles and corners