Expansion Joint and Crack Tape

The Ultimate Joint and Crack Sealant System

Excellent Chemical and Temperature

Resistance for Joint or Crack Sealing

The FluoroGrip® Joint and Crack Sealing Systems provides a highly chemical and temperature resistant method for sealing joints or cracks in compatible materials and substrates such as concrete.

FluoroGrip Joint Tape is a fluoropolymer-based tape manufactured with advanced technology pressure sensitive adhesive for “peel-and-stick” ease of use. It is the ideal replacement for traditional chemical resistant caulks, offering all the advantages of FluoroGrip linings such as:

- Elastomeric (to 330% elongation)

- Superior reliability of a fully fluorinated material

- Highest resistance to harsh chemicals

- Temperature resistance to 450° F

- Easier installation than traditional sealants

- Reduced labor and installation costs

- No VOCs and / or hazardous solvents – safer

FluoroGrip Joint Tape protects against corrosive/reactive liquids leaking into expansion, control joints and cracks in concrete and other materials. It stands up to a wide range of harsh chemicals such as organic and inorganic acids, solvents and more. Review the PDF flyer below for additional information.

FluoroGrip Joint Tape – Physical Properties†

| Property | Method | Result |

| Tensile Strength @ Break | ASTM-D882 | 24 Mpa |

| Elongation @ Break | ASTM-D882 | 250%-330% |

| Initial Tear Strength –1 Mil | ASTM-D1004 | 4.9-5.3 N |

| Ozone Resistance | ASTM-D1149 | Excellent |

| Weather Resistance | ASTM-D816 | Excellent |

†Varies depending upon film FEP, PTFE, ECTFE, PVDF, ETFE, PFA and MFA

Disclaimer: The information printed herein is furnished free of charge and is based on technical data that Integument Technologies, Inc. believes to be reliable. It is intended for use by persons having technical skill, at their own discretion and risk. The handling precaution information contained herein is given with the under- standing that those using it will satisfy themselves that their particular use conditions present no health or safety hazards. While the information contained herein is believed to be correct, Integument Technologies,Inc. makes no representation as to the accuracy of it. Since the conditions of product use are beyond our control, Integument Technologies, Inc. assumes no liability in connection with any use of this information. The evaluation of the product described herein under enduse conditions prior to specifications is essential. Nothing contained herein is to be taken as a license to operate under or as a recommendation to infringe on any patents.

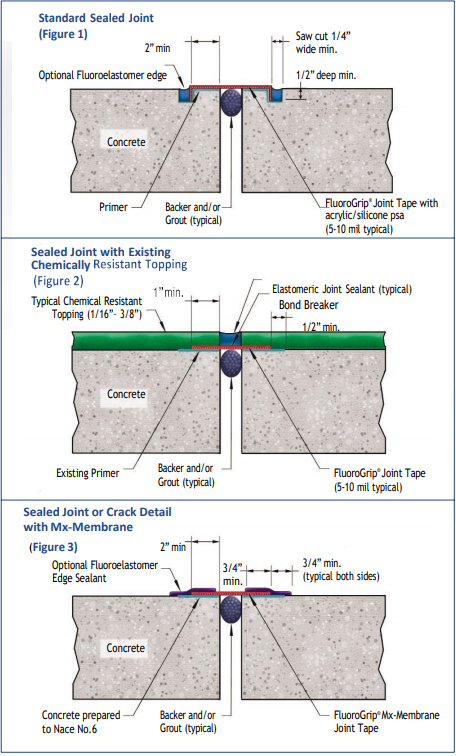

Installation Instructions

- Clean and remove unsound surfaces – high pressure water, grit blasting, grinding or sanding.

- If no existing primer is present, one can be applied to the concrete (Figures 1 and 2). If no primer is to be used, the Mx-Membrane joint tape only requires that the concrete be

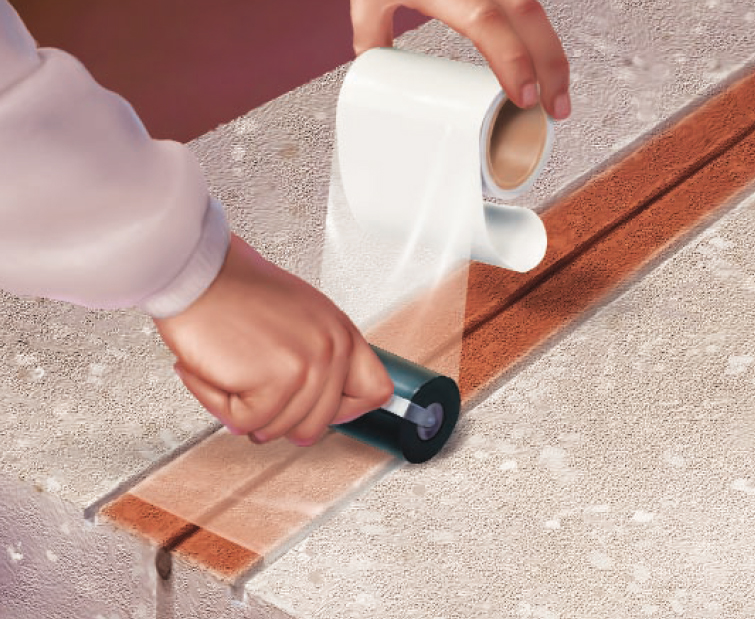

prepared to Nace No. 6 (Figure 3). - Remove backing from sealant tape and apply over joint or crack (typically 4 to 6 inches wide). Activate

pressure sensitive adhesive with roller or burnishing tool, using moderate pressure. - Edge Sealing Procedures for FluoroGrip® joint tape:

Figure 1 – Saw cut terminate the tape and seal tape edges with a fluoroelastomer caulk

or equivalent.

Figure 2 – Apply chemically resistant primer over the joint and seal tape edges with a fluoroelastomer caulk or equivalent.

Figure 3– Apply fluoroelastomer caulk or equivalent.

For more information on FluoroGrip® joint and crack sealant systems, contact your Integument Technologies representative today. For questions regarding application requirements or other technical issues, contact our Technical Services department at 716-873-1199.