Paint Replacement Applique for Application onto Department Of Defense Shelters and Vehicles

Preface to 2022 Update:

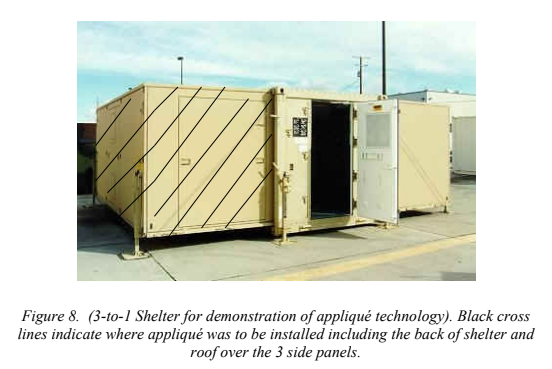

The original case study was prepared in 2010 as a result of a Small Business Innovative Research (SBIR) contract awarded to Integument Technologies “Automated Delivery of Pigmentation for Camouflaging Patterns for Composite Shelters.” One of the deliverables in the SBIR project was to have a composite shelter (see Figure 8) coated with Integument’s FluoroGrip® applique style (peel-and-stick) paint replacement film.

The shelter will have been outside, exposed to the weather of the northeast USA climate for 12 years by July 2022. We obtained photographic evidence of the longevity of FluoroGrip® in February 2022, appended to the end of this report.

In brief, FluoroGrip® film is withstanding the test of time. The only blemishes that have appeared were due to the thermal expansion/contraction of some underlying sealant/filler materials.

Project Summary

The objective of this project was to design a prototype system that would randomly distribute camouflage pigment in a non-repeating pattern over composite structures that will comply with Air Force specifications. Currently, the U. S. Air Force (USAF) uses metal and composite shelters that have a unique visual and radar signature.

In order to maintain this unique targeting signature for existing metal shelters, each must be hand painted in a random manner that is not repeated for any other shelter.

In addition, the Air Force is currently investigating composite technologies to replace the existing design and materials for tactical shelters. The composite materials can be impregnated with pigment, but are difficult and expensive to paint using conventional Chemical Agent Resistant Coatings (CARC) that are required for all DoD shelters.

Thus, this project was also tasked with developing a coating system that would meet all current military requirements (including CARC) with additional requirements that included long term survivability and cost effectiveness.

To achieve the objectives outlined above Integument Technologies, Inc. developed a unique paint replacement, peel-and-stick applique system that effectively provide the DoD with a coating system that was environmentally friendly and easily adapted to randomly distribute camouflage patterns onto pre-fabricated composite shelters or vehicles.

This applique system was field demonstrated and showed that one could effectively eliminate the need for painting and repainting existing shelters and equipment.

In summary, Integument Technologies developed and fabricated a pre-designed camouflage patterned peel and stick appliqué technology that:

- Has highly accurate random and fixed designs – predetermined and fabricated off site in interchangeable kits

- Has capability for rapid application, removal, and interchangeability in the field

- Is lightweight in design

- Is reusable

- Has zero environmental impact, i.e. have zero volatile organic carbon (VOC), zero hazardous air pollution (HAP), and zero toxic release inventory (TRI)

-

Has Long term survivability (20 years or greater) and outstanding severe environment protection capability including the capability to withstand and protect structures and equipment from:

- Corrosion

- CARC’s

- CBR

- Electromagnetic Environmental Effects

Appliqué Material Testing

Preliminary Field demonstration results on USMC EFV

Although the target application for this project’s appliqué technology is specific to shelters and housing, Integument has other ongoing work under ONR USMC and Missile Defense Agency (MDA) contracts that demonstrate field results under extreme conditions that support the use of appliqué for long-term protection of Air Force shelters as described in this project.

For example, The Missile Defense Agency (MDA) program that has demonstrated appliqué paint replacement as a superior short- and long-term solution to severe corrosion problems encountered on equipment, vehicles, and stationary structures located at MDA bases in the South Pacific.

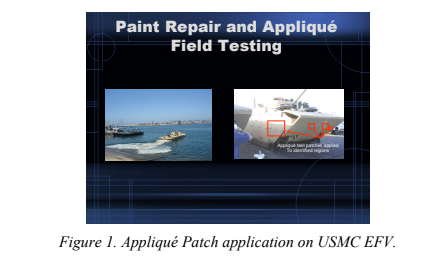

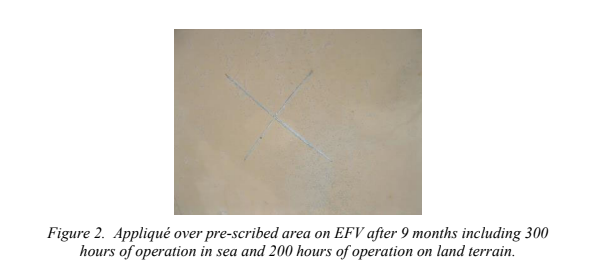

In addition, Integument has worked on a project coating several military land vehicles. Figure 1 illustrates the application of paint replacement appliqué on the USMC’s Expeditionary Fighting Vehicle (EFV formerly AAAV). Figure 2 illustrates the effectiveness of Integument’s appliqué patch over a pre-scribed area on the EFV after 9 months that includes 300 hours of sea operation and 200 hours of land terrain operation. Not shown are prescribed and damaged areas that illustrate corrosion onset in areas not protected by appliqué.

Figure 3 illustrates an M-113 coated with Mil-color tan appliqué for a DoD field demonstration. The objective was to demonstrate the ease and quickness of coating and removing appliqué from the vehicle. The vehicle took approximately 1 day to coat and 4 hours to remove, providing the vehicle back to the exact condition it was received.

Solvent, Fire and Smoke Density Testing

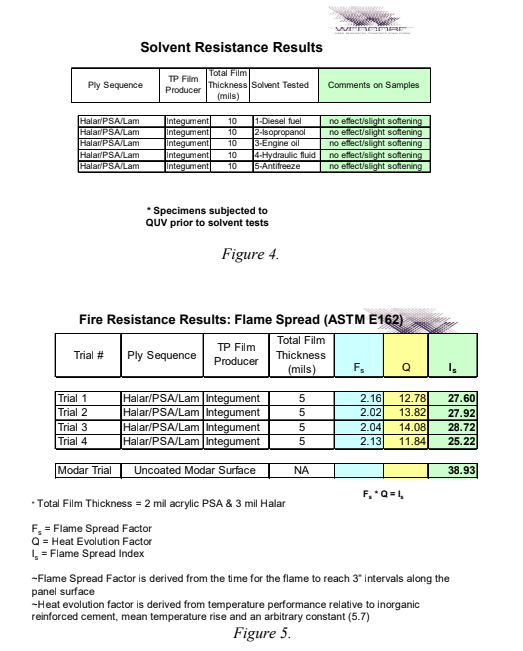

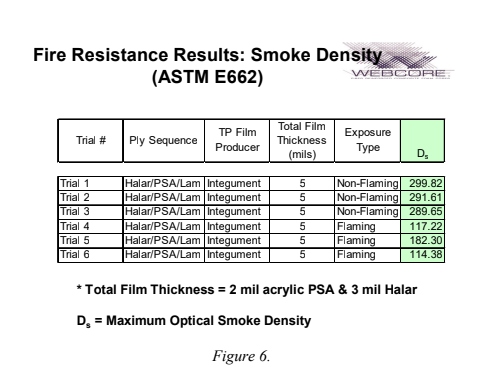

Figures 4, 5, and 6 show the results obtained by a third party, Webcore (one of the Navy’s shelter fabricators) on Integument’s paint replacement appliqué.

Results shown in Figures 4, 5, and 6 above indicate an excellent alternative to other paints or coating systems currently under consideration for applications on Air Force composite housing structures. According to Webcore the results listed above demonstrate that appliqué is acceptable and either the best or close to the best material with respect to Solvent Resistance, Fire Spread/Resistance, and resulting Smoke Density.

These characteristics are coupled with the appliqué inherent long-term severe environment resistance as demonstrated in our ongoing USMC and MDA programs described above. In addition, the following sections will demonstrate other properties that are superior to other paints and coating systems under evaluation in this program.

UV Testing

One of the Air Force’s objective for shelters is to build structures having at least 20 year lifetime capabilities with minimal maintenance and repair. Thus, it is important that base composite materials used in fabricating the structures have long-term lifecycle features and equally important, that the coating system for these composite structures have the same lifecycle capability.

Currently there are few if any paints or other coating systems that can supply this required lifecycle capability other than fluoropolymer-based appliqués that have no known degradation process even under the most severe environments.

In addition, advanced coatings (e.g., vinyl esters, urethanes, or polyamide-based coatings), have problems withstanding many severe environment conditions related to UV exposure, but also offer little protection to underlying substrates (in this case, composite shelter materials).

Fluoropolymer appliqués have the severe environment resistance required for 30-year integrity as well as the ability to protect and provide a 30-year lifecycle to any underlying substrate.

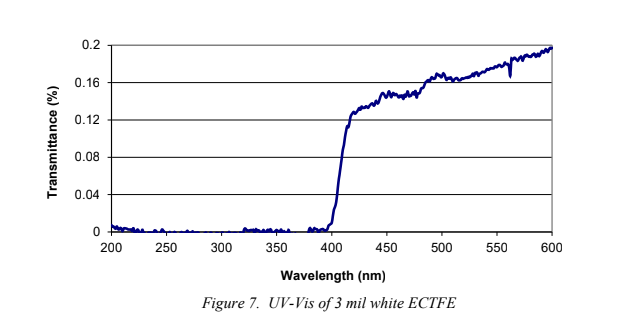

Figure 7 illustrates the UV spectrum of a white pigmented fluoropolymer appliqué film showing that the applique essentially blocks all UV radiation thereby providing total long term UV protection to any underlying substrate.

CARC Compatibility

In addition to UV protection, Integument’s fluoropolymer appliqués offer CARC compatibility including excellent resistance to chemical agent adsorption (measured via Chemical Agent desorption tests) and subsequent decontamination compatibility. Results have shown the appliqué materials to be superior to any other coating system investigated by the testing laboratory sponsored by the Army Research Laboratory (ARL). A full report prepared by one of the Army’s approved testing facilities (CUBRC) is available upon request.

Camouflage Design and Field Testing

Due to the nature of our camouflage applique the design, fabrication and field testing are not included in this case study but can be accessed under the proper conditions via contacting Dr. Andrew Hope at Integument Technologies, Inc.

Apply Appliqué to Shelter (Conduct Vendor Demonstration at USAF site)

The last task of this project was to demonstrate the field application of Integument’s appliqué technology on a full shelter. The U. S. Air force (project funding agency provided a shelter located at Hanscom AFB located outside of Boston MA.

Figure 8 illustrates the 3-to-1 Shelter that was chosen for this demonstration. The black cross hatch lines indicate the area of the shelter that will be used to demonstrate the appliqué technology. In addition, the back side and top of the cross-hatched section of the shelter will also be coated.

Materials and Shelter Surface Preparation for Demonstration

Eight rolls of 3’ x 100’ of 5 mil tan ECTFE appliqué pre-colored via pigments to match Mil- Std color Tan 686- (Fed color code #33446) had an acrylic 4 mil pressure sensitive adhesive applied on the back for securing the appliqué to the shelter surface.

A three member installation team arrived at Hanscom AFB on June 28, 2010 and began to inspect shelter for required surface preparation. In general, the shelter was clean due to several days of hard rain and the team decided that the only surface preparation required was to clean surface of shelter with a dry cotton cloth. No use of the power washer was required.

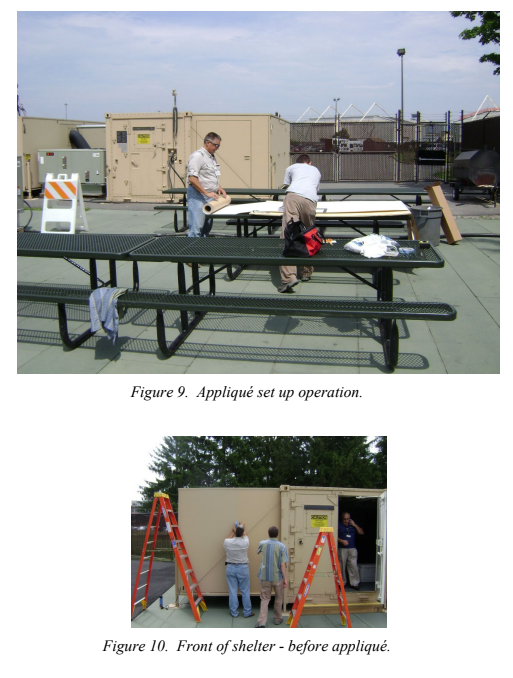

Figure 9 shows the setup of the operation and illustrates the ease of installation: Specifically, appliqué technology allows one to coat existing structures, vehicles and equipment or prefabricated sheets with a CARC compliant material that is nontoxic, contains no HAP or VOC’s and requires no HAZMAT support during the coating operation.

Appliqué Installation

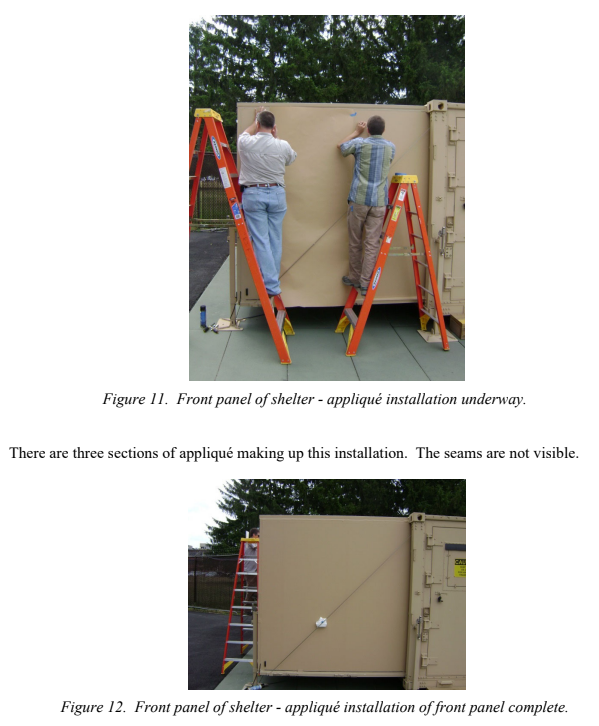

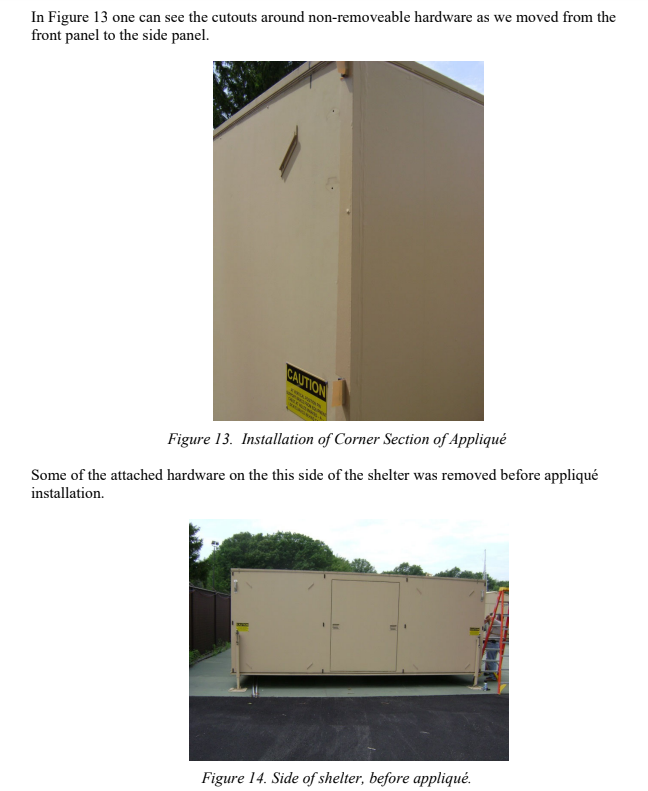

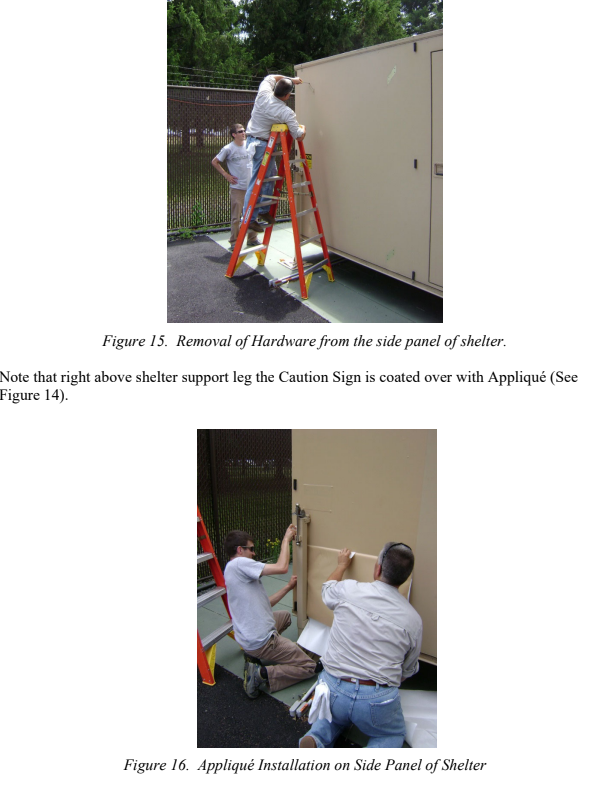

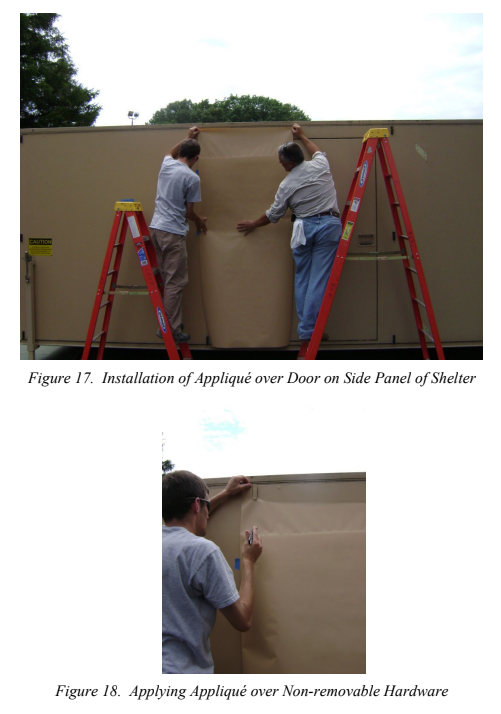

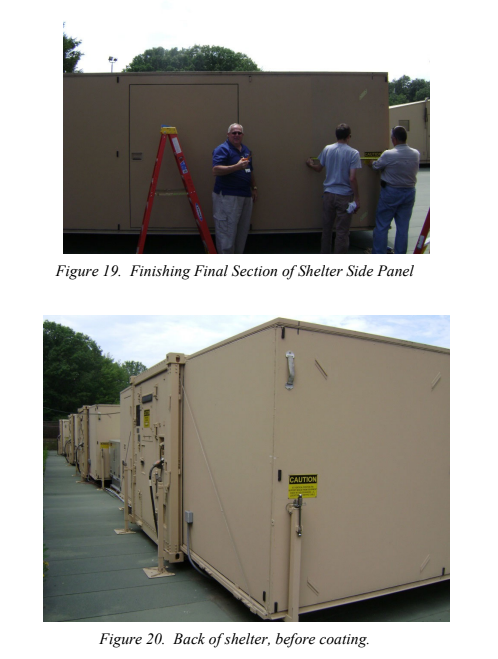

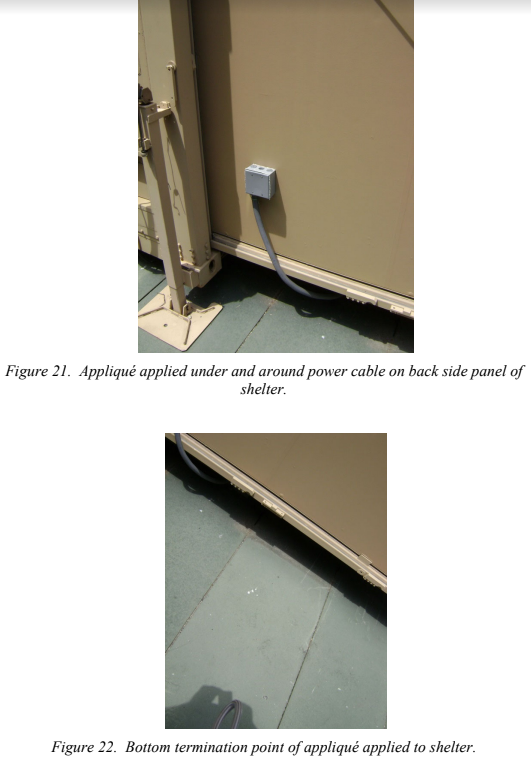

The following figures (9-26) and comments describe the step-by step installation of appliqué to the shelter sides.

In Figure 11, the cable that could not be removed is seen. Installation had to be performed by slipping the appliqué under the cable that led to some wrinkling problems on the back of shelter:

Note that the left side of this panel (Figure 17) is complete and that the Caution Sign on the left side of the side panel is clean. (Compare to Figure 1.16 that showed that the appliqué film was originally coated over the Caution Sign and then removed after finishing that section)

In Figure 19 the whole panel is almost complete, (including door where one can see that the handle has been effectively trimmed around) excepting about a 3 foot side section being measured.

The wrinkling on the back panel (Figure 23) was due to the difficulty in sliding the roll of appliqué under the cable. This was not as apparent on the front section because the installers were able to use their right hands instead of left to apply appliqué to the top corner.

6” Appliqué tapes were used to cap and connect the roof of the shelter with all of the side panels (This illustrates appliqué on back side panel shown in Figure 1.20). Full coverage of roof was then applied so that no ingress areas from roof to side panels were left. Note again that the seams are very difficult to see. Compare the edge in this Figure to that in Figure 20:

The entire job including 3 side panels and the roof over these panels took about 6 hrs to complete with two people. Note that the temperature for this day was in the mid 90’s with humidity around 90 percent.

Summary

In general, the installation went very well. The installation figures show that the appliqué color is somewhat darker than the paint on nearby shelters. This is because the painted shelters have been exposed to long term weathering and UV radiation that has bleached the paints on the existing shelters.

Repainting of these older shelters is cost prohibitive due to the need to have HAZMAT on site because of the hazardous nature of currently specified CARC paint for these shelters.

The most difficult part of the installation was applying the appliqué under cables and cutting around various non-removable components. Some wrinkles and bubbles were unfortunately visible due to the fact that we had to work around the existing hardware.

In addition, the shelter contained removable gaskets that are put in place after the shelter is expanded. For future applications we would advise the removal of these gaskets such that we could apply appliqué and terminate within the gasket joint. Subsequent replacement of the gasket over these areas would leave better seals with better aesthetic features.

While the field demonstration went well as illustrated, it is Integument’s recommendation that the appliqué be applied to pre-fabricated walls and structures associated with the shelters before the components are assembled. This is especially true when considering the Air Force objective of using composite materials instead of the steel structure that was coated at Hanscom AFB.

We note that application of paint to composite materials is difficult (especially the use of CARC paints) due to bonding mismatches between composite materials and mil-std paints. This problem can easily be resolved via the appliqué solution that utilizes various pressures sensitive adhesives designed specifically for the material that the appliqué is destined to be used on.

Finally, one of the concerns of the program management was that the appliqué currently cannot be manufactured in sizes that can coat an entire side or wall of a shelter without seams. The demonstration performed and described in this report shows that the seams are barely visible up close and not visible at 15 feet away from the shelter.

In addition, the seaming technology used for appliqué creates a permanent bond that eliminates the problem of liquids or other materials creeping under the seams to the shelter base material.

Thus, based on our demonstration, the seaming issue has been minimized and future development of appliqué technology envisions the use of larger equipment that can fabricate appliqué films large enough to eliminate the seaming issue all together.

For additional information concerning this case study, or inquiries about the capabilities of Integument Technologies, please call us or submit a contact form through our website.