Plasma Treatment Technology

The Science Of Plasma Surface Treatment Makes It Possible

Integument manufactures FluoroGrip® using patented, advanced surface activation science and pressure-sensitive adhesive technologies.

Our proprietary cold gas plasma surface modification process makes it possible to apply adhesives and coatings that bond permanently to fluoropolymer films, including PTFE, ECTFE, FEP, and more.

FluoroGrip® materials do not rely upon etching or other inferior forms of physical degradation to promote adhesion. The chemical covalent bond formed between the FluoroGrip® materials and the adhesive is permanent – enabling FluoroGrip® to be used in applications where no conventional adhesive fluoropolymer sheet or film product can. The bond withstands a variety of thermal and mechanical stresses including extreme temperature cycling, UV, humidity and a wide range of aggressive chemicals without delaminating from the adhesive.

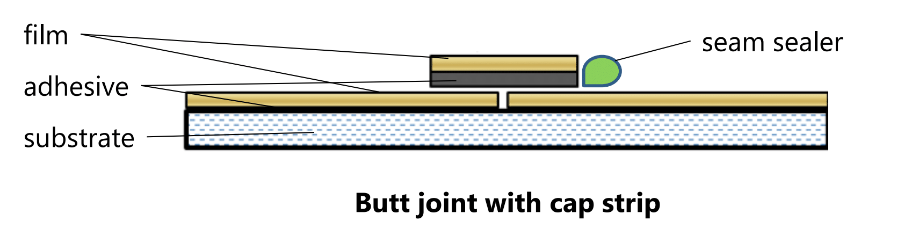

Two-Sided Surface Modification

FluoroGrip® surface modification is normally performed on both sides of the film, and on one side is laminated with pressure sensitive adhesive with a release liner. On installation, the release liner is removed to expose the adhesive. The top side is modified but does not have an adhesive. The top side can then be coated with a variety of caulks, coatings, sealants or adhesives if necessary. Two – sided is required when installations involve seams or cap strips. The exposed side of the film, also treated, can then bond to the adhesive of an over layer. Integument can recommend a variety of fluoroelastomer caulks and sealants for sealing seams and edges.

One-Sided Surface Modification

- As an option, FluoroGrip® surface modification can be limited to one side of the film, which is then typically laminated with a pressure sensitive adhesive with a release liner. On installation, the release liner is removed to expose the adhesive.

- One-sided is required when installations require that the exposed side of the film preserve the virgin (untreated) fluoropolymer properties.

- The single-sided product is used in the anti-graffiti product and mold release liners, and ideal for other non-stick, low-friction uses such as conveyors.