Case History: Cold Storage Chiller-Pan Protection

Download case history in PDF.

The following study illustrates the use of Integument’s new FluoroGrip ® peel-and-stick fluoropolymer films for preventing corrosion and extending equipment life for a California cold storage facility.

The company operates facilities that store fresh fruits at temperatures down to 34°F. This allows the goods to be sold during more profitable times of the year. The equipment used to keep the rooms chilled includes chillers and aluminum drip pans employed to collect condensation that is generated by the chillers. The acidic (H2SO3) condensation is collected in the pans and then piped away for proper handling.

The Problem

- New and existing collection pans are constructed of aluminum which rapidly corrodes when exposed to acidic environments.

- The cold rooms utilize SO2 gas to fill the room in order to eliminate insects and prevent fungi from growing.

- The moist environment found in the rooms, combined with the SO2 gas, produces a weak sulfurous acid (H2SO3) solution when moisture condenses on the chillers. This weak acidic solution is destroying the oxidized surface layer of the aluminum which is what provides corrosion resistant properties of aluminum.

- The result is a rapid destruction of the pans in less than two years.

- Each pan measures approximately 34′ long by 2.5′ wide by an average depth of 2″.

- Each pan costs $6,000 and currently requires replacement every two years or less. The facility owners were faced with a challenge: How do we extend the life of the collection pans from 1-2 years, to 6-10, years with minimal costs and operational disruptions?

The FluoroGrip ® Engineered Solution

The facility owner actively experimented with traditional epoxy-phenolics and other conventional paints and coatings. Traditional coatings were unsatisfactory for several reasons: The operational downtime, combined with application costs for sandblasting and metal preparation was prohibitive. The pans are constructed of a relatively thin gauge of aluminum, which sandblasting permanently damaged by warping. The coatings did not withstand the corrosive environment and failed to protect the aluminum from corrosive attack.

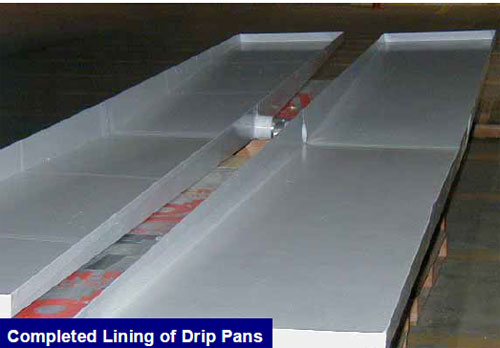

Working with Integument engineers, the customer selected a FluoroGrip ® – P (PTFE), 10-mil fluoropolymer film which incorporates a proprietary plasma surface activation and acrylic adhesive technology to create a peel-andstick fluoropolymer film. After a simple solvent wipe (isopropyl alcohol) surface preparation, the film was applied to both the interior and exterior pan surfaces — much like wallpaper. The project was finished by sealing all film edges with FluoroGrip ® SB-100 brushable fluoroelastomer edge sealant.

System Benefits

- Minimal downtime & disruptions – no extensive sandblasting or other surface preparations, no multi-coat paint systems or cure times were required.

- Cost effective – each pan required minimal labor and material costs compared to other, less effective, options.

- Performance – Fluoropolymers commonly referred by trade names such as Teflon ®, Halar ®, and Kynar ®, are the most chemically inert plastics known to man. Combined with Integument’s, state-of-the-art plasma surface activation and adhesive technologies, the system is expected to exceed the desired 6-10 year service life.

Teflon ® is a registered trademark of the Dupont Company

Halar ® is a registered trademark of Ausimont-Solvay

Kynar ® is a registered trademark of Ato-Finatechnical

Disclaimer: The information printed herein is furnished free of charge and is based on technical data that Integument Technologies, Inc. believes to be reliable. It is intended for use by persons having technical skill, at their own discretion and risk. The handling precaution information contained herein is given with the understanding that those using it will satisfy themselves that their particular use conditions present no health or safety hazards. While the information contained herein is believed to be correct, Integument Technologies, Inc. makes no representation as to the accuracy of it. Since the conditions of product use are beyond our control, Integument Technologies, Inc. assumes no liability in connection with any use of this information. The evaluation of the product described herein under end-use conditions prior to specifications is essential. Nothing contained herein is to be taken as a license to operate under or as a recommendation to infringe any patents.